Automatic Inverted

Package Size 230.00cm * 130.00cm * 430.00cm Package Gross Weight 400.000kg The Marked Prices Of Our Products Are All Ran;

Basic Info.

| Model NO. | TQ-17 |

| Certification | CE, GMP |

| Voltage | 220V |

| Computerized | Computerized |

| Customized | Customized |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Online Support, Video Technical Support |

| Heating Area (M²) | 2 |

| Cooling Area (M²) | 0.5 |

| Condensation Area (M²) | 3 |

| Mezzanine Design Pressure (MPa) | 0.3 |

| Feed Port Diameter (mm) | 150 |

| Tank Design Pressure (MPa) | 0.09 |

| Transport Package | Wooden Case with Steel Frame |

| Specification | 4.6*3.6*7.1M |

| Trademark | JNBAN |

| Origin | Wenzhou, China |

| Production Capacity | 100pieces/Year |

Packaging & Delivery

Package Size 230.00cm * 130.00cm * 430.00cm Package Gross Weight 400.000kgProduct Description

The Marked Prices Of Our Products Are All Range Prices Of The Entire Product Series.If You Need a Detailed Quotation, Please Send An Inquiry At The Bottom Of The Page.

intuitive and convenient;

High pressure: The design pressure of the extractor is 55 MPa, and the working pressure is 50 MPa;

Safety: With hardware security protection measures, and software system has the function when overpressure the pump will be stopped ;

Convenience: Extractor clamp quick-opening structure, and use an electric hoist to lift seal plug and loading barrel;

Energy conservation: CO2 can be recycled, and the CO2 in the extractor and cylinder can be recover lower than 0.8 MPa;

High efficiency: Optimize extraction process, the capacity can be increased more than 50 %.

Accessories:

The tank is equipped with CIP cleaning automatic rotating spray ball, temperature gauge, pressure gauge, explosion-proof sightglass lamp, sight glass, quickopening feeding port, etc., to ensure easy operation and meet GMP standards. The inner cylinder ofthe equipment is made of 304 and 316L.Extraction - During this process, biomass is placed inside extraction vessel with a solvent(Ethanol, C02, and so on.) to remove

soluble components, followed by filtration and separation process. The solvent then needs to be recovered from dry biomass

| Series technical parametes | TQ-1 | TQ-2 | TQ-3 | TQ-4 | TQ-5 | TQ-6 |

| Volume(L) | 1200 | 2300 | 3200 | 6300 | 8500 | 11000 |

| Tank design pressure (MPA) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| Compressed air pressure (MPA) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Feed port diameter (mm) | 400 | 400 | 400 | 500 | 500 | 500 |

| Heating area (m²) | 3.0 | 4.7 | 6.0 | 7.5 | 9.5 | 12 |

| Condensation area (m²) | 4 | 4 | 5 | 5 | 8 | 10 |

| Coling area (m²) | 1 | 1 | 1 | 2 | 2 | 3 |

| Filtration area (m²) | 3 | 3 | 3 | 5 | 5 | 6 |

| Slag gate area (m²) | 800 | 800 | 800 | 1000 | 1000 | 1000 |

| Energy consumption (kg/h) | 245 | 325 | 345 | 645 | 720 | 850 |

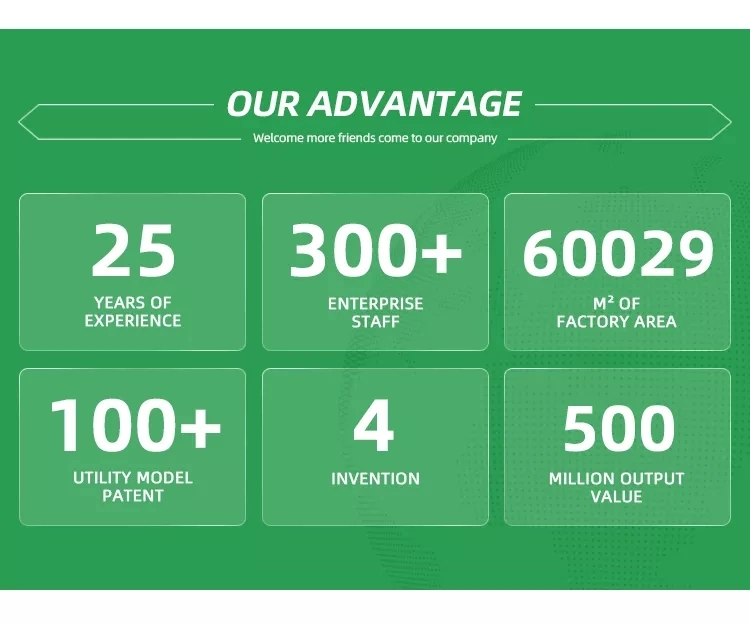

Q1: who are we?A1: We are a factory based in CN , Zhejiang , Wenzhou, No. 420 Binhai 23rd Road, Binhai Park, Economic Technological Development Zone, We are always welcome your visit.Q2: How can we guarantee quality?A2: We can provide the whole production process to you by video or live stream, we also have International Certification like CE, ISO9001, etcQ3: What kind of products can extractor process?A3: All kinds of liquid material.Q4: How to ship extractor?A4: Flat Rack+containerQ5: What is the delivery time?A5: 45 daysQ6: What is the after-sales service type?A6: Engineers onsite to guide installation, commissioning and trainingQ7: What can you buy from us?A7: Extractor, concentrator, evaporator, vacuum belt dryer and other stainless steel products.

You may also like

Send inquiry

Send now